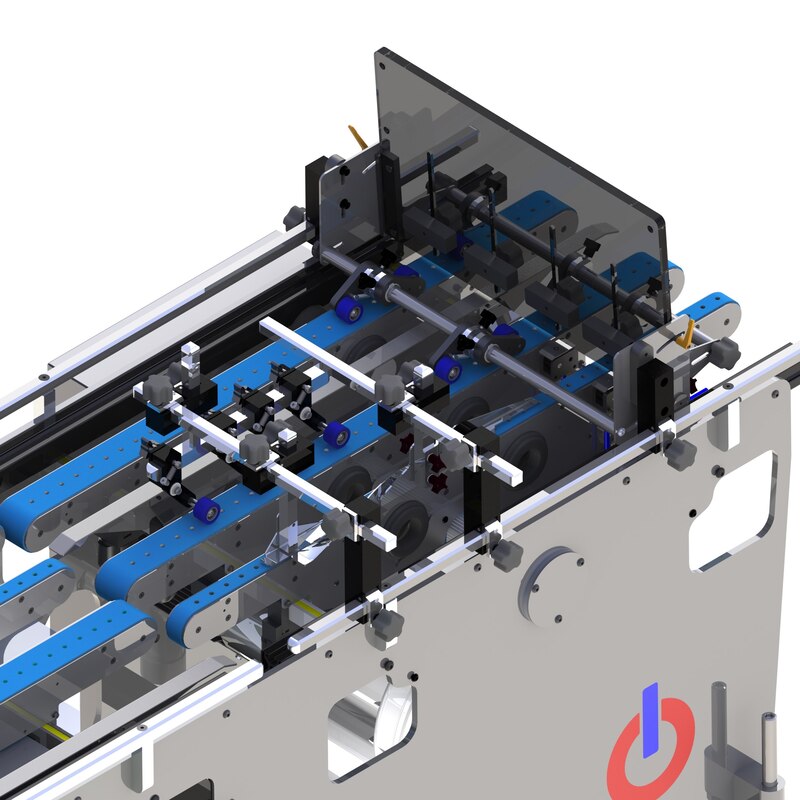

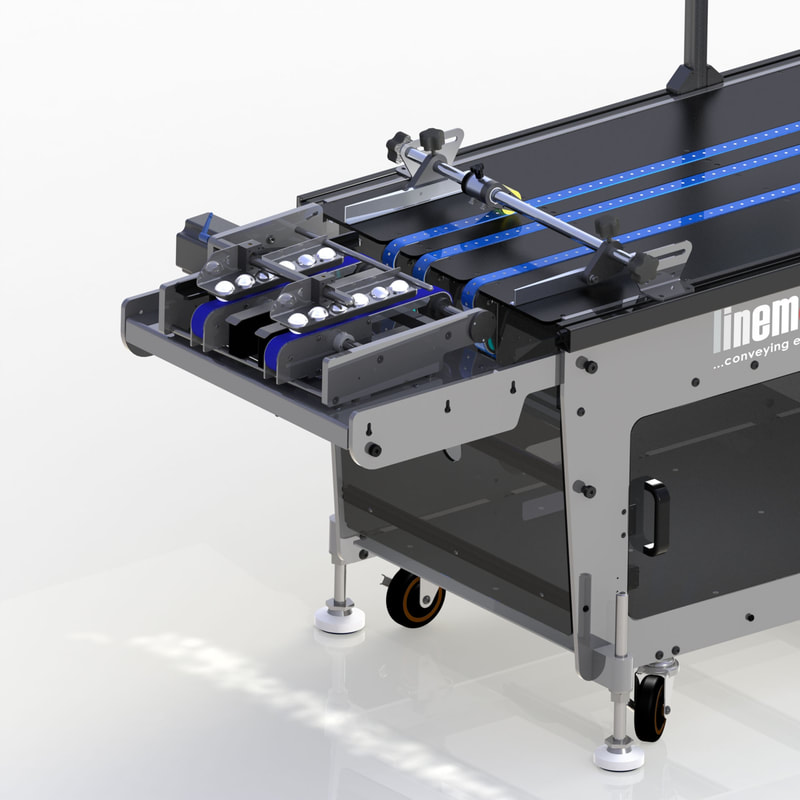

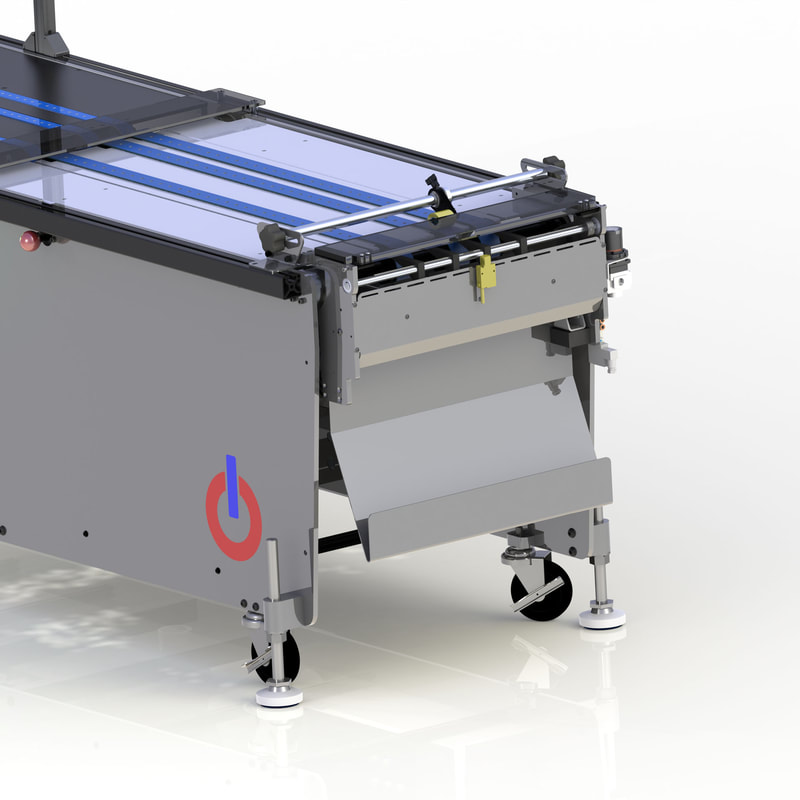

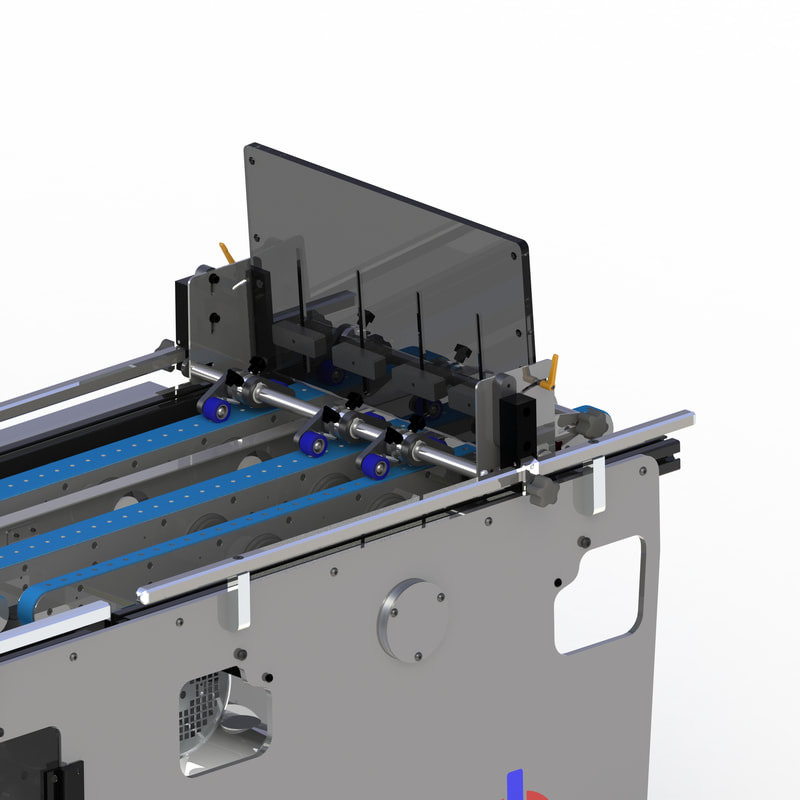

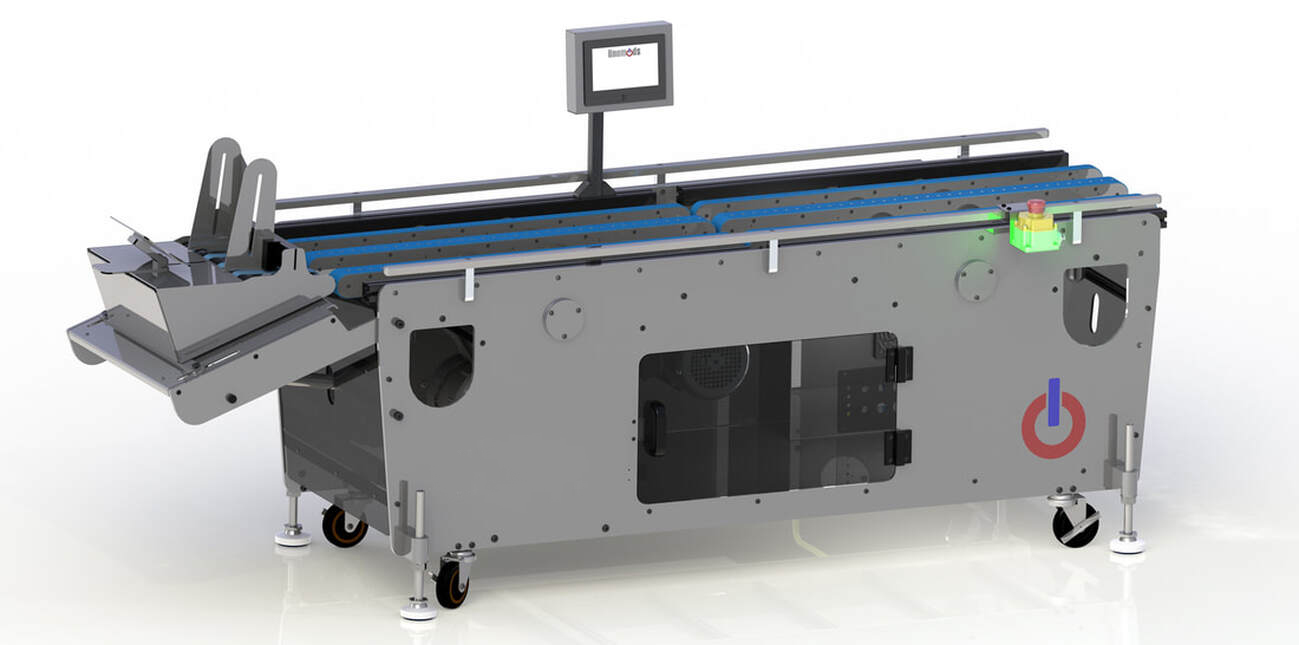

Linemods VMC 206 Vacuum Transport / Finishing Conveyor

Product ID: 18334

New Listing

Year: NEW

Make: Linemods

Model: VMC 206

Click here to contact us about this product »

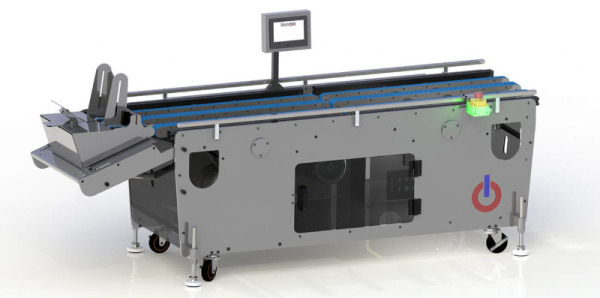

Linemods VMC 206 Vacuum Transport / Finishing Conveyor

Linemods equipment is designed with a balance of easy operation, longevity and innovation from over 25 years of experience in the post press/production environment – All equipment equipped with a 2-year built-in warranty.

Quality Without Compromise:

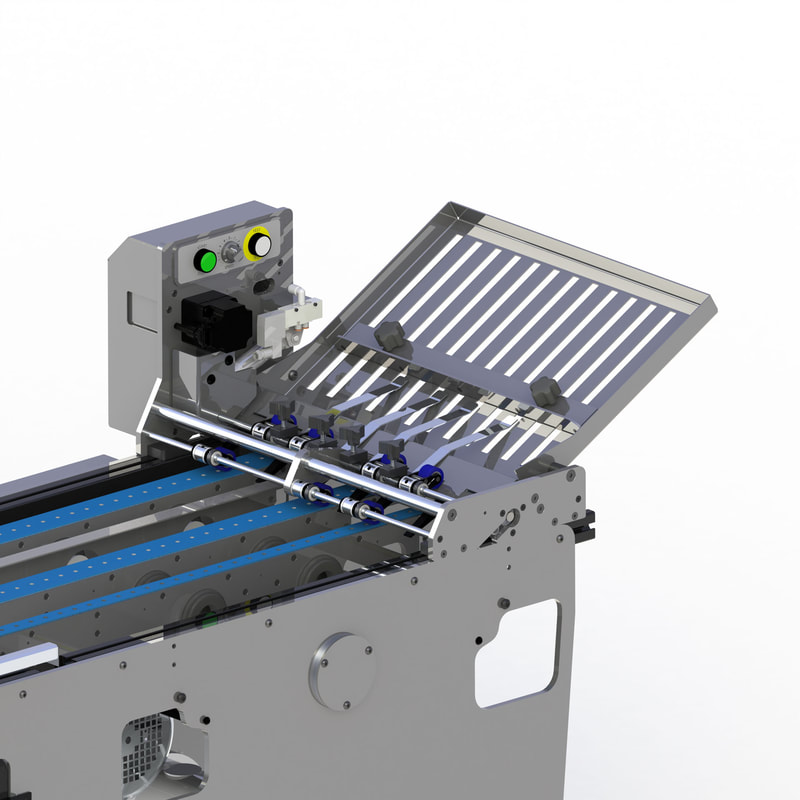

Linemods VMC line vacuum transport/finishing conveyors - Quality without compromise, from the innovative vacuum system to the powder coated aluminum frames. Perform quick, easy, tool-less setups with the highest quality deck components available – We have designed this conveyor line from the ground up to cover the most demanding of environments. Plow folding, scanning, ink jetting or placement - Linemods VMC line provides outstanding performance and operator versatility and will prove to be the most user-friendly conveyor available today.

Design:

- Tool-less design – No tools needed to perform most set-ups/changeovers

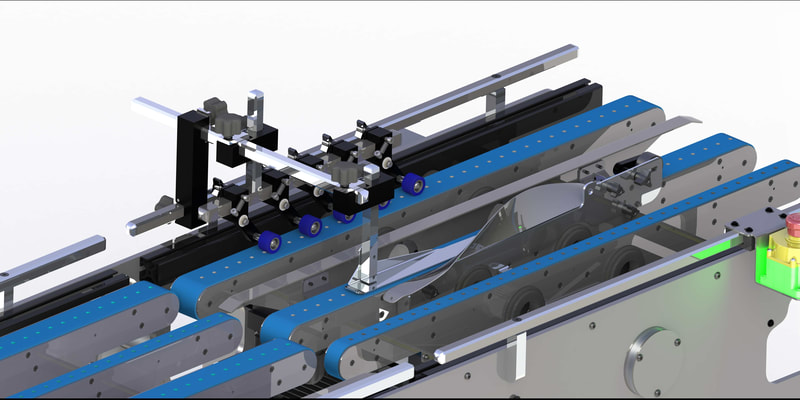

- Vacuum belt construction is of a friction resistant backer with a 55D rubber cover, perforated for vacuum integration – The slippery backer provides an extremely low coefficient of friction (belt to fixed surface)

- Each segment of transport is vacuum regulated (2 segments per tube). This vacuum system is engineered for consistent; even pull-down - “loaded” or “open deck” – STALL RESISTANT AND POWERFUL

- Component design – All pivot points have bushings - expense not a factor in assembly – all components designed to last

- 2-year warranty – We are confident with our parts/equipment designs and back new equipment

Vacuum System Engineered for Application:

- Self-modulating

- Quiet

- Powerful

- Stall-resistant

- Efficient

- Expandable

Two tube widths available to handle most any job (1” and 2”) - Design promotes quick removal if desired or easy adjustment – Belts can be changed in minutes. Vacuum tubes are split into two chambers – this ensures constant vacuum where you need it the most.

- Skewable (stream separation and side register)

- Built in side guides (quick register – full length)

- Adjustable (built in scales to streamline set-ups)

- Removable (without tools in minutes)

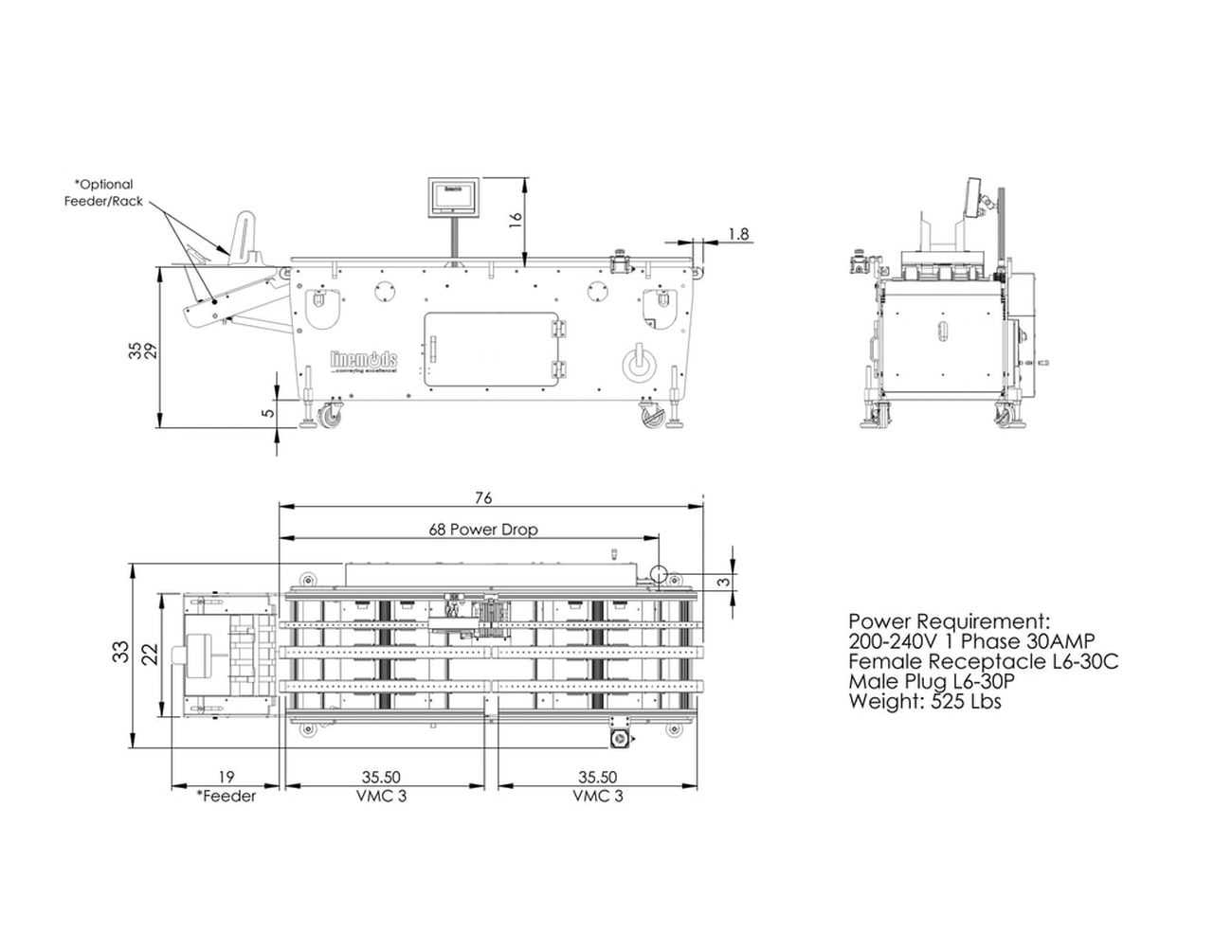

- Custom belts/transports available 3’ and 5’ lengths (standard builds)

Attributes:

- Advanced technology vacuum system

- AC Vector Drive

- Bi-directional

- 3/8” Powder coated aluminum frames

- Clutched handwheel

- Adjustable height (6”)

- Rubber coated vacuum conveyor belts

- Interchangeable 1” & 2” drives

- Split vacuum chambers

- Tool-less adjustments

- Cantilevered infeed and discharge

- Adjustment scales

- Integrated encoder mount

- I/O: Start, Stop, Feed and Speed

Product Capacity:

- Width: Min. Width: 1-20+” / Max. Width: 21”

- Product thickness range: .05mm - 13mm

- VMC Configuration: (3'x3’)

- Max Speed: 450’- 600’ minute

- Gross weight: 525 lbs

- Electrical: 200-240v 1 Ph / 30amps

Accessories: